// VCSEL and Photo Diode Alignment Simplified

Aligning a 4-channel VCSEL and a 4-channel photo diode together on a PCB, using conductive epoxy, is a challenging application for most telecom companies that develop and manufacture VSR or LR communication devices.

The coupling efficiency is key to making this assembly successful. A bonder capable of post-bond accuracies of +/- 1 micron is essential.

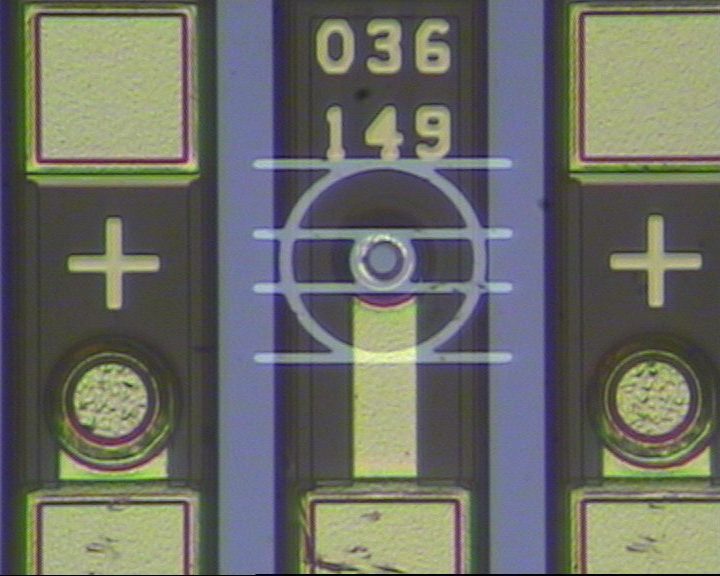

One approach to this difficult alignment is to use a pattern generator via software – either an integrated part of an existing software suite or a stand-alone version.

After the VCSEL has been placed, images are created by the software and those images are then used to pick/place the photo diode relative to the VCSEL. The disadvantages of using this method are minimal - changing the field of view (magnification) cannot be done without first calibrating the images. But changing the field of view does not necessarily help. Instead, keeping the field of view the same will make the process reliable and repeatable.

A second approach is the popular and simple method of using a glass mask tool. This tool consists of a die collet with a quartz piece that has an etched chrome pattern which is based on the design of the assembly. This will allow alignment of the VCSEL to the glass, placement of the VCSEL and then alignment of the photo diode relative to the VCSEL and glass mask. This may sound complicated but with the right equipment, it can be easily achieved.

To find out more about either of these options, contact us.

08/26/2014, created by: Robert Avila