For thirty years, Finetech has been supporting start-ups as well as global technology leaders in the development of innovative semiconductor products. Our high-accuracy die bonders are currently used e.g. to build MEMS-based sensors and imaging sensors for a wide range of applications, 5G modules and optical transceivers for data communication, or power lasers for industrial and medical applications.

But we don't stop there. Our Prototype-to-Production approach ensures a seamless transfer of R&D processes to the production environment and automation of all assembly steps without additional development effort.

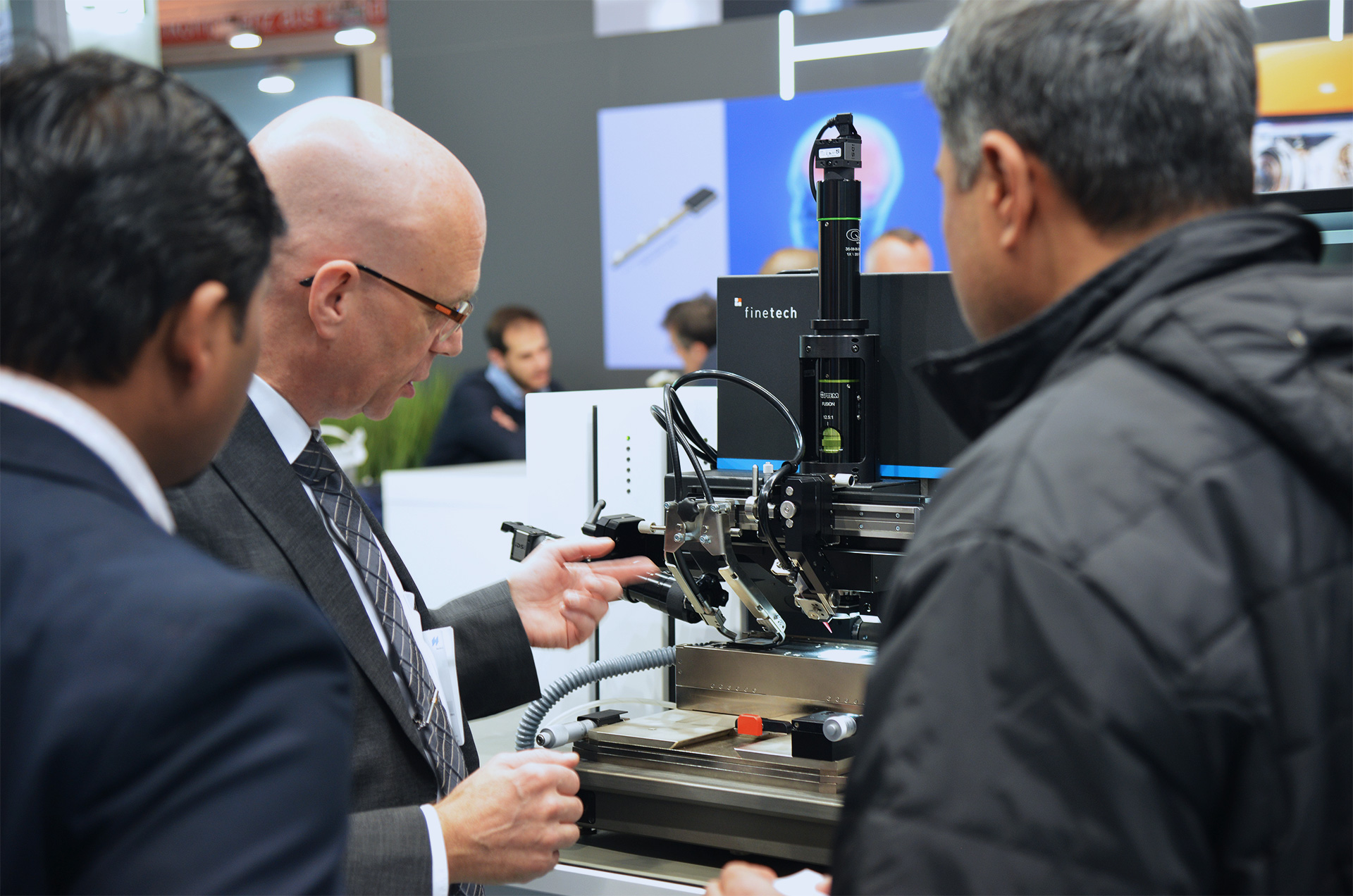

Check out our Productronica 2021 highlights and learn more about how to make Finetech your one-stop equipment partner for R&D, prototyping and production.

The Most Powerful Tool for Lab & Research

We have listened carefully to our customers and created the the most powerful tool for lab & research - the FINEPLACER® pico 2. The multi-purpose, manual die bonder with placement accuracy down to 3 µm is quick to set up and easy to operate, making it the ideal choice for fast and flexible product development and prototyping in R&D labs and universities.

By combining application flexibility, technological diversity, process reliability and compatibility with Finetech’s automated production bonders, the FINEPLACER® pico 2 offers an outstanding return on investment and is a natural starting point on the journey from concept to final product. World premiere at Productronica 2021!

The Efficient Solution for Production

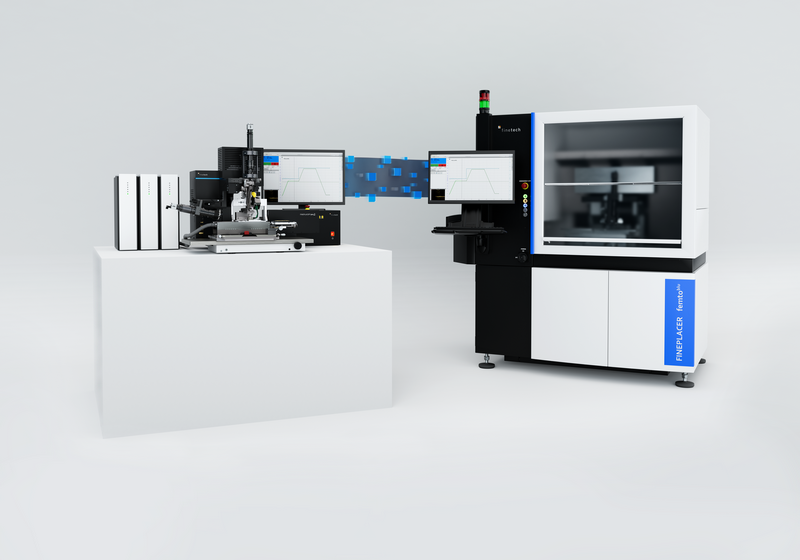

We also present the automatic placement and assembly system FINEPLACER® femtoblu which allows you to keep the versatility and precision of the processes developed on the FINEPLACER® pico 2 and combine it with fully-automated handling steps and pattern recognition. Process parameters which have already been qualified on the development system can be further used on the automatic bonding platform, as their tools and modules share the same technical basis.

You can automate your placement and assembly processes in a fast and easy way. With a placement accuracy down to 2 µm @ 3σ, the FINEPLACER® femtoblu is geared toward the demanding requirements of MEMS-based sensors, image sensors, power lasers, silicon photonics and quantum technology.

Prototype-to-Production

All new FINEPLACER® die bonders follow Finetech's "Prototype-to-Production" approach of a cross-system, unified hardware and software platform. It enables R&D processes to be seamlessly transferred in all their technological diversity from the development lab to the production environment. This opens up adapted product development strategies with minimized financial risk, especially for users with tight budgets and uncertain projects.

Developers start their projects with a comparatively low initial investment on a manual FINEPLACER® R&D bonder such as the FINEPLACER® pico 2. In the creative phase, they benefit from the open design and the freedom of a versatile and adaptable development system. Once the new product is ready for production, the R&D processes are transferred to a FINEPLACER® production system like the FINEPLACER® femto blue and automated with ease.